Dongfeng asphalt Road pothole Hot regeneration repair truck

Application range

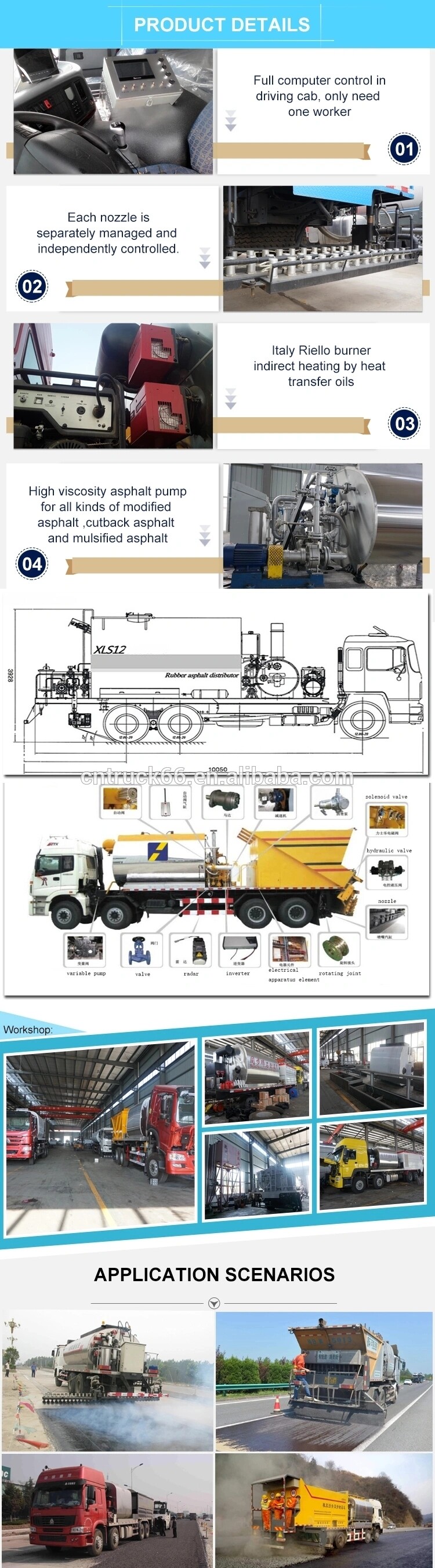

Asphalt Road pothole Hot regeneration repair truck is a professional asphalt road comprehensive regeneration and repair equipment. It is mainly composed of chassis, roller heating system, hydraulic system, storage box, emulsified asphalt spraying system, pavement heating wall, old material recovery system, etc. It has complete asphalt mixture heating and heat preservation functions, emulsified asphalt spraying, asphalt pavement heating Various functions such as repairing and recycling of old materials. It is suitable for repairing various asphalt pavement diseases on high-grade highways, airports, municipal roads, etc. nationwide. Construction is not subject to seasonal restrictions; it achieves the rapid arrival, rapid repair and rapid evacuation required by highway maintenance. It has the characteristics of high efficiency, low energy consumption, less pollution and convenient operation.

Performance advantages

1. It adopts Dongfeng Tianjin special modified chassis, Cummins 180 horsepower engine, and the maximum driving speed can reach 90KM/H, which meets the needs of rapid construction and rapid evacuation of the expressway; the exhaust emission meets the Eruo Ⅴ standard.

2. It is equipped with a burner heating system, which has the functions of heating cold materials and heat materials. It will not be unable to be repaired on the road due to asphalt mixture. At the same time, old materials can be regenerated on site, saving raw materials and costs to the greatest extent. The effect of minor repairs and medium repairs is excellent;

3. PLC touch screen intelligent control. Centrally control the drum heating, stirring, heating plate heating and other actions on the panel, and there are indicator lights and alarm lights to diagnose the fault.

4. It has an integrated emulsified asphalt spraying system to supplement the oil content of the regenerated material, a hand-held spray gun with automatic hose recovery function, and a self-cleaning function for the asphalt pipeline.

5. The hydraulic system is powered by the chassis engine through the power take-off, and has a hydraulic output interface to provide hydraulic power for various hydraulic tools.

6. With special LED construction lights to meet the needs of night traffic construction on the road section with large traffic flow; equipped with LED safety warning lights, effective sight distance of more than 200 meters; convenient night construction can effectively remind the car to pay attention to avoid.

7. Bring its own old material recovery bin, and drive the tilt through the electric control hydraulic pressure to take away the waste materials and garbage generated in the construction process.

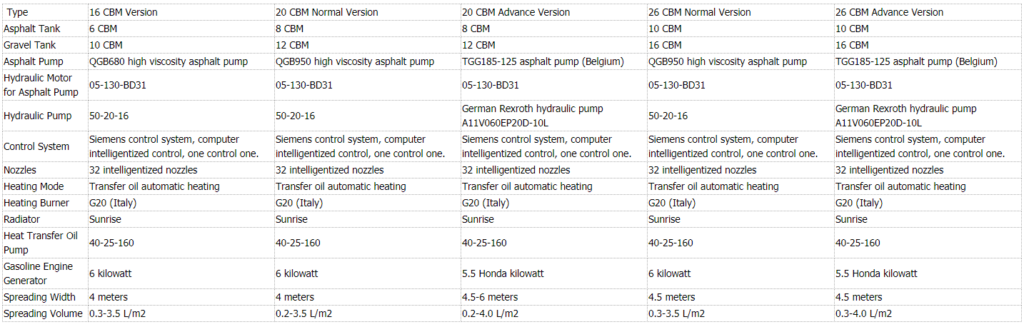

specification:

| Device name | Dongfeng Tianjin asphalt pavement thermal regeneration maintenance vehicle | |

| Drum volume | 1.5 cubic | |

| Curb quality | 10905kg | |

| Vehicle size | 7600×2400×3050 mm length×width×height | |

| Drum heating parameters | ||

| 100,000 kcal | ||

| Diesel | ||

| 1000KG | ||

| Spin-drop | ||

| Infrared sensor | ||

| Hydraulically controlled automatic hopper | ||

| Electronic control system | ||

| PLC programmable control (Siemens) | ||

| Touch screen / button | ||

| Hydraulic system | ||

| 40ml/r | ||

| Integrated solenoid valve | ||

| 395ml/r | ||

| Fully electronically controlled | ||

| 150L | ||

| Automatic unloading mechanism | ||

| Automatic unloading mechanism | Powered by an electronically controlled hydraulic motor, the drum reverses and discharges automatically | |

| Discharge speed | Adjustable speed | |

| Integrated emulsified asphalt spraying system | ||

| Hose length | 8 meters with automatic recycling function | |

| Emulsified asphalt box | 45L | |

| Diesel cleaning tank | 17L | |

| Emulsified asphalt pressure bottle | 20L | |

| Integrated heating plate | ||

| Heating area | 2.5 ㎡ | |

| way to heat up | Thermal radiation | |

| District heating | Divided into left and right zones (both can be heated in sections or heated in whole) | |

| Additional features | The heating plate can be rotated and moved horizontally | |

| Used material recycling bin system | ||

| Old silo volume | 300L | |

| control method | The electronically controlled hydraulically driven silo is erected and laid flat, reducing the labor intensity of workers’ old material recycling | |

| roller | ||

| Compaction width | 715mm | |

| Exciting force | 15KN | |

| Lifting method | Adopt gantry lifting mechanism, side hoisting, easy operation and high safety | |

| Chassis | ||

| Dongfeng Motor | ||

| Cummins ISB 180 | ||

| Country Ⅴ | ||

| Other configuration | ||

| With LED arrow indicator, improve the safety of construction | ||

| With hydraulic power output connector, can provide power for external hydraulic tools | ||

| Matching | ||

| Matching | ||

Dongfeng asphalt Road pothole Hot regeneration repair truck Working parameter: