We produce 5000liters mini lpg gas filling station X-ray testing for every welding line and ensure 100% qualified;Hydraulic testing at pressure 2.21Mpa,Sandblasting before painting,Two layers of Anti-corrosion painting before final painting Adding steel base with the tank;Installation of pipeline,valves and other equipments,Painting of pipeline,Filling testing before delivery.

China lpg filling station Product Description:

1. It is used for refilling lpg cylinders in different size such as 3kg,5kg,6kg,12.5kg and 50kg.

2. It is designed with two major functions: Truck Discharging & Cylinder Refilling with 1 Pump

3. It is optional for digital Filling Scale or automated filling dispenser(single nozzle or double nozzle) with Auto Filling Cut-off, Thousands of Record store, net and Gross Filling data

4. Pump of mobile filling station is optional : Vane Pump & Coro-Flo Pump, Turbine Pump, standard is Chinese brand but you can choose Corken or Blackmer Brand.

5. Motor: standard is Chinese brand but also optional for ABB or SIEMENS Brand, Static-free, 380V 3 Phase, 5.5KW to 10KW

6. Pipeline : 2″ Steel pipe with safety return valve, strainer, one-way valve, cut-off valves.

7. Explosive Proof Central Control Panel for whole 5mt lpg skid station system

8. Other Equipment : Sunshade for filling area, gas Leakage Detector,ex-proof lamp, water sprinkler system with sprinkler nozzles

5000liters mini lpg gas filling station specification:

| 1.995T(5M3) LPG storage tank | |||||||

| Filling gas | LPG (propane) | ||||||

| Design Specific Gravity | 0.42 Kg/L | ||||||

| capacity | 5M3 | ||||||

| External Dimensions (length*width*height) | 3070*1620*2200mm | ||||||

| Tank dimension (length*diameter) | L3070*D1600mm | ||||||

| tank weight (nominal) | 2030kg | ||||||

| max payload weight | 1995kg | ||||||

| tank material | Q345R | ||||||

| Tank body design thickness | 8.53mm | ||||||

| End cover design thickness | 8.51mm | ||||||

| design temperature | 50 0C | ||||||

| working temperature | -20~50 0C | ||||||

| Corrosion allowance | 1.0 mm | ||||||

| design pressure | 1.77 MPa | ||||||

| Hydraulic test pressure | 2.22 MPa | ||||||

| leak test pressure | 1.77 MPa | ||||||

| Heat treatment type | Wholly get rid of tress | ||||||

| Main parts specification | |||||||

| Liquid level meter | Type | UZFAL-2.5FM | |||||

| Model | Magnetic level gauge | ||||||

| Nominal pressure | PN2.5Mpa | ||||||

| Surveying range | 50~2300mm | ||||||

| Precision | 2.5Grade | ||||||

| Safe valve | Type | A42F-2.5-50 | |||||

| Model | Inner full lift | ||||||

| Nominal pressure | PN2.5 MPa | ||||||

| Nominal diameter | DN50mm | ||||||

| Opening pressure | 1.68-1.76 MPa | ||||||

| Closing pressure | 1.51~1.59MPa | ||||||

| Complete opening pressure | <2.12 MPa | ||||||

| Loading and unloading device | Model | Quick tie-in | |||||

| Nominal Diameter | Inlet Gas phase | DN50mm | |||||

| Outlet gas phase | DN50mm | ||||||

| Drain outlet phase | DN50mm | ||||||

| Inlet Liquid phase | DN50mm | ||||||

| outlet Liquid phase | DN50mm | ||||||

| Pressure meter | YN-100T | ||||||

| Temperature gauge | WTQ-280 | ||||||

| Cut-off valve | J41N-40 | Normal pressure | PN2.5 MPa | ||||

| Normal diameter | DN50MM | ||||||

| DN32MM | |||||||

| DN25MM | |||||||

| DN20MM | |||||||

| Safety valve of pipe | Type | A21F-25 | |||||

| Normal pressure | PN2.5 MPa | ||||||

| Normal diameter | DN15MM | ||||||

| Security reflux valve | Type | AH42F-25 | |||||

| Normal pressure | PN2.5 MPa | ||||||

| Normal diameter | DN25MM | ||||||

| Back pressure valve | Type | H42N-40 | |||||

| Normal pressure | PN4 MPa | ||||||

| Normal diameter | DN50MM | ||||||

| Discharging pipe | Length | 4M | |||||

| Normal diameter | DN50/DN25MM | ||||||

| Shock-absorbing pipe | Length | 500MM | |||||

| Normal diameter | DN50MM | ||||||

| Flange | Normal pressure | PN2.5 MPa | |||||

| Normal diameter | DN65MM | ||||||

| DN50MM | |||||||

| DN32MM | |||||||

| DN25MM | |||||||

| DN15MM | |||||||

| Lpg gas pump (YQB15-5) | Flow (m³/h) | 15.5 | |||||

| Inlet pressure (MPa) | ≤2.0 | ||||||

| outlet pressure difference (Mpa | 0.5 | ||||||

| Pump rotate speed (r/min) | 780 | ||||||

| motor power (KW) |

5.5 | ||||||

| Inlet aperture (mm) | 50 | ||||||

| Outlet aperture (mm) | 50 | ||||||

| Temperature rangeºC | -40~40 | ||||||

| Weight(kg) | 108 | ||||||

| Explosive-proof motor | 7.5HP(5.5KW), Explosive Proof, | ||||||

| Dual Frequency 220V to 690V, 50Hz and 60Hz supplies applicable | |||||||

| LPG cylinder filling machine | Model | BSC-150 | |||||

| Electricity voltage V | AC220 | ||||||

| Power(w) | 40 | ||||||

| Weighting scale | Can fill 0.5kg to 150kg LPG cylinde | ||||||

| Measurement Precision | ±0.5% | ||||||

| Rated Working Pressure | 1.6Mpa | ||||||

| Temperature range ºC | -40~40 | ||||||

| Anti-explosion Rate | Exhibit II BT4 | ||||||

ChengLi Lpg station details:

Lpg skid sration type exhibition:

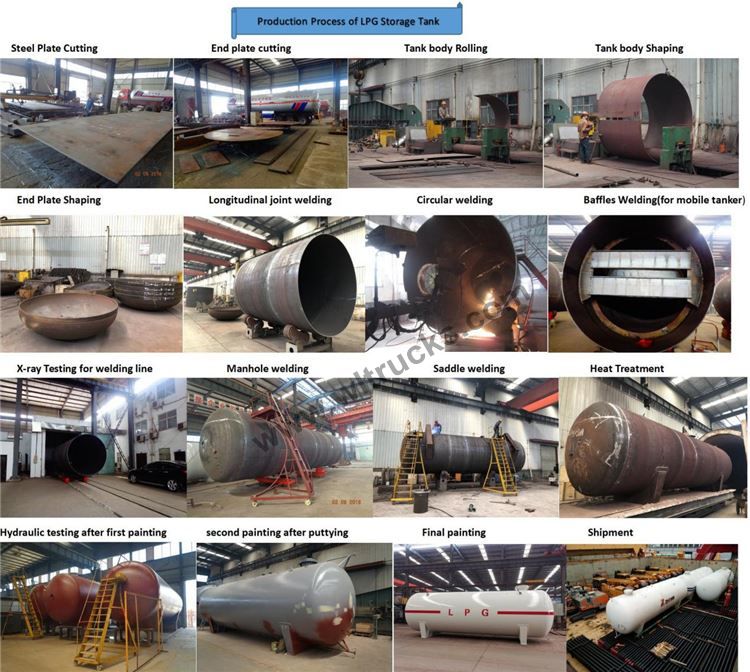

lpg lpg gas filling station Production Process:

We can supply whole package solution of lpg station building as follows

- Medium: Liquified Petroluem Gas

- Tank material: Q345R, shell 10mm,end plate 12mm

- Tank Design Pressure: 1.71Mpa,

- Tank Acessories: Safety Valve, Level Gauge, Water Sprinkler System, Air out Valve, Drain Valve,

- Filling System:

- 2 Units LPG filling scales in Digital Control,

- 1 Units 2″ LPG pumps with 380V-3 Phase 5.5KW Explosive Motor,

- 1 Units Electrical Control Box with Air Switch,

- 1 Units Leakage Detector with 1 Sensor,

- Solid Steel Base, Steel Sunshade for Filling Area,

- Whole Set Pipeline System with all valves,

FAQ:

Q1: What is your product name?

A: 5000L to 200000liters lpg skid station

Q2: What size of lpg skid station can you supply?

A: We can supply lpg skid station from 5cbm to 50cbm,the most popular size is 10m3 and 20m3 lpg skid station, 5tons and 10tons lpg skid station.

Q3: What’s the production standard of your lpg skid station?

A: GB-150.1~4-2011 or optional for ASME VIII Division I U STAMP

Q4: Where is your factory located? Can we visit your factory?

A: Our factory is located in Suizhou City,Hubei Province,central China,which is famous for special vehicles.You can take high speed train to Wuhan railway station,Hankou railway station or Wuhan Tianhe International Airport.

Q5: What’s your payment term?

A: 40% deposit by T/T and balance by T/T before shipment.

Q6: How many days can I get my the lpg skid station after paying deposit?

A: Usually our delivery time is 30 days.

Q7: Can you offer local installation service and local after sales service?

A: The lpg skid station can be operated after arrival and we will offer guidance video of operation.

Our customers are located in 127 countries and regions around the world