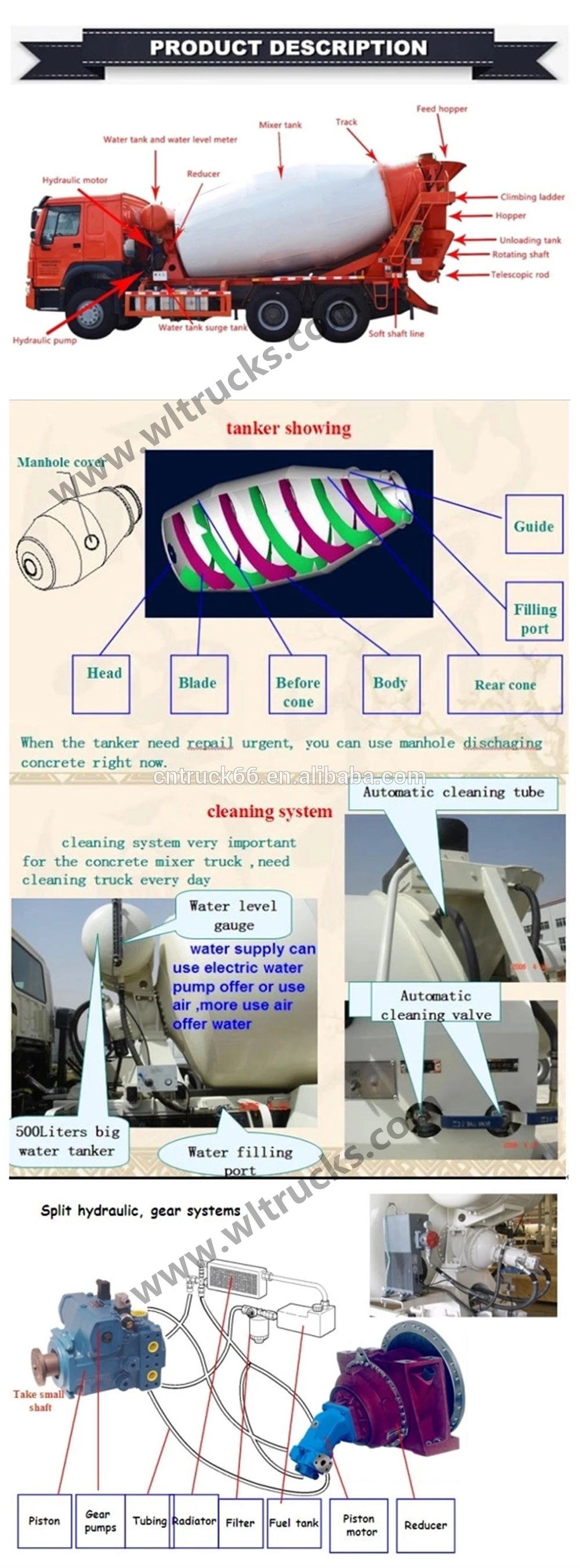

products description:

Our mixer truck is mainly used in cement mixing station, construction field and other place.The capacity ranges from 2m3 to 18m3, meeting customers’ various needs.

It is can loading and unloading by itself. After discharging the concrete, the mixer drum will be cleaning automatically by its water suppling system.

Our concrete truck mixer consists of seven main parts. Theyare hydraulic pump, reducer, rotating drum mixer, operation system, drum cleaning system,concrete feed hopper,concrete outlet hopper.

2m3 self loading concrete mixer truck Specification:

|

Diesel Engine

|

>Model: CLW4T22T-105

>Total displacement, no Cylinders: 4330cc-4 in line >Injection: direct with mechanical control >Cooling: water, dry air filter >Max. power: 78Kw(106Hp) >Max. torque: 330Nm@2400rpm |

|

Electric System |

>Alternator:28V–500Wa (18A)

>Battery: 2x12V–60Ah (272A) >Road light system, rear working lights. |

|

Steering

|

>4 steering wheels, Assisted by means of load-sensing power steering on 4 steering wheels.

|

|

4×4 Four-wheel Drive |

>Hydraulic torque converter transmission with closed Piston walking pump (EATON) and reverse gear control on the steering wheel.

>Electro-hydraulically controlled mechanical gearbox for “working speed” and “road transfer speed”. >Speed:2 forward gears 2 reverse gears 2 forward gears: Ist 0-7.0Km/h, IInd 7-20kph

2 reverse gears: Ist 0-7.0Km/h, IInd 7-20kph |

|

Axles and Wheels |

>Front wheel fixed stable

>Rear wheel is controlled by two cylinders as articulated type with 30 degrees steering angle. >Tires: 20.5-16-12PR >Maximum L: AD3540kg, 450kPa, RIM:9.75 |

|

Brakes

|

>Internal wheel hub disc service and emergency brakes acting on the 4 wheels, activation with mini servo pump on independent dual circuit

>Negative type parking brake, with internal wheel hub discs on the front axle |

|

Water System |

>24V “Self-priming” volumetric water pump with quick-suction

>Maximum capacity: 90 liters/minute >Two tank with a total capacity of 2*250 liters. >Water feeding to the drum controlled by means of electromagnetic flow meter and feed liter reading on the cabin display >Water pump activation from the driver’s seat >Washing vehicles outside by water blast gun via high pressure water pump |

|

Mixing and Unloading |

>Double-cone drum with double-spiral mixing screws and convex bottom

>Geometrical drum volume: 3100 liters >Drum rotation speed: 16rpm >Concrete produced as: 2.0 m³ >Counter frame mounted on “heavy-duty” ball fifth wheel, with 270° hydraulic rotation and automatic locking by means of hydraulic brake. Drum rotation by means of a gear pump with variable flow rate and an orbital hydraulic motor in open circuit with adjustable handle control manually positioned in the cabin and at the rear of the machine. >Drum raising up to the horizontal position by means of 2 double-acting jacks >Unloading chute with mechanical tilting by means of one handle controlled and 90° rotation, independent from the mixing drum inclination >Removable chute if unloading from hopper >2 unloading chute extensions provided as standard equipment |

|

Equipment Hydraulic System

|

>Gear pump: DEHONG (brand)

>Maximum flow rate: 20/50 liters/min. >Maximum pressure: 16MPa >3-Handles controlled with multi-function joystick >Aluminum heat exchanger for hydraulic oil cooling >Pressurized open-circuit intake with oil filter replaceable from the outside |

|

Loader

|

>Auto weighting function, Loading device with Teeth bucket and lifting arms controlled by double-acting hydraulic cylinders

>Automatic unloading hatch driven by a mechanical lever >Volumetric capacity: 400 liters >Number of loading times: around 5 |

|

Cab

|

>Closed cab with heating system

>Tilting front window >Anatomic seat with flexible suspension and height adjustment |

|

Service Refill Capacities

|

>Fuel tank: ………………….100liters

>Total hydraulic system capacity: …….100 liters >Engine oil: ……………….16 liters |

|

Weights

|

>Operating weight: 6000 kg

>Max gross weight: 10800 kg >load-carrying capacity: 4800 kg |

cement mixer truck detailed picture:

mixing truck Structural composition drawings: