10000L to 15000L Railway dust suppression truck Adopt Dongfeng Tianjin chassis, wheelbase 3950 to 4500mm, cummins 170-190 horsepower, eight gear box, 1000-20 nylon tires.

Top-loading configuration: The tank body is an 8-cubic circular tank, with anti-corrosion inside the tank body, with heating function, front impact, rear sprinkling, side spray, anti-aircraft gun, dust suppression spray bar (with rotary telescopic function). The spray rod is 3.5-5 meters above the ground.

The rear platform is equipped with an 8KW auxiliary generator set. Two 1.5KW electric motors (with stirring function) are added inside the tank. Remote control operation spray bar rotates up and down, left and right, domestic well-known brand slewing support, big brand oil cylinder.

Disinfectant mist spray truck products introduction:

1. Mobile vehicle disinfection system fogger spray truck Also called railway dust suppression truck, The whole vehicle adopts full intelligent electric control operation, vehicle spray system, mixing function and rotating arm function.

2. All functions except the chassis and the water tank are self-priming and self-draining.

3. The spray system is equipped with a single-vehicle flow meter (used to measure the amount of dust suppressant sprayed by each section of train leather). The spray system is equipped with a hook stop spray system (contact induction spray, between two sections of train leather) Stop spraying), with vehicle number identification and recording functions.

4. The vehicle sprinkler system, single-vehicle flowmeter and vehicle number identification and recording functions are all connected and reacted to the intelligent computer screen.

5. When the spraying principle is in standby state. The spray arm is located above the maintenance and recovery platform parallel to the rail; when in working state, the locomotive with the bow is passed.

6. The spray arm rotates to a position perpendicular to the carriage, and at the same time adjusts the height to 30cm above the train carriage, the vehicle identification number is detected by the vehicle identification system, and under the control of the PLC, the spray drum is stopped according to the principle of the hook gear. Start the spraying operation; after the spraying is completed, the system switches to the cleaning state, the pipeline and the spray head are cleaned, and the cleaning liquid is returned to the mixing tank.

7. When the vehicle speed is running in the range of 0.5-1.0km/h, the spray control system can achieve uniform coverage of coal transport vehicles and ensure that the safety and normal operation of the locomotive vehicles are not affected.

Railway dust suppression truck Working parameter:

1. Heating method, adopting the equipment imported from Italy to reheat the dust suppressant in the existing heat preservation tank, adopting the internal circulation type, effectively increasing the heat preservation area and heating area, so that the entire interior of the tank is heated uniformly;

2. Equipped with video monitoring function, video monitoring can cover the operator and the entire spraying operation process, and has the function of playing back and storing each storage, can record 2-3 months of work, which is convenient for later query and maintenance;

3. Boom recovery function, with manual control and automatic control, and install a limit device to maintain smooth operation, if the equipment fails to stop, our products can be quickly recovered and rotated in 30 seconds without electricity The function of the boom guarantees the running of trains and the safety of vehicle personnel.

4. Man-machine interface. In the cab, all the operation functions of the whole vehicle can be completed, the generator set is switched on and off, the spray arm is set automatically, and various parameters of the generator set can be monitored in real time

5. (Including generator output, voltage, oil pressure, operating time, starting times, etc.), including spray arm (rising height, rotation angle, flow data, stirring motor operation, heating device operation and other parameters ).

10000L to 15000L Railway dust suppression truck Specification:

| Announcement model | CLW5164TDYD5 | Environmental protection | Have |

| Vehicle wheelbase | 4700 | Exemption | Have |

| Engine horsepower | Cummins 170 190hp | Mixing function | 1.5KW*2 |

| Tank volume | 10 – 15cubic | Heating equipment | Imported from Italy |

| Drive method | Electric + hydraulic | Flow reading | Can read the flow of each car box and the flow of a single train |

| Secondary power | 8KW | Vehicle identification | Can be adapted to each train and container number |

| way to control | Siemens PLC + touch screen + wireless remote control + manual | Cleaning system | Can clean the pipeline |

| Boom height above ground | 3-4.5 meters | Emergency recovery | The boom can be recovered manually in an emergency |

| Spray method | Hook stop spray system | Job monitoring | Comprehensive operation of monitoring equipment in the cab |

Disinfection truck structure composition:

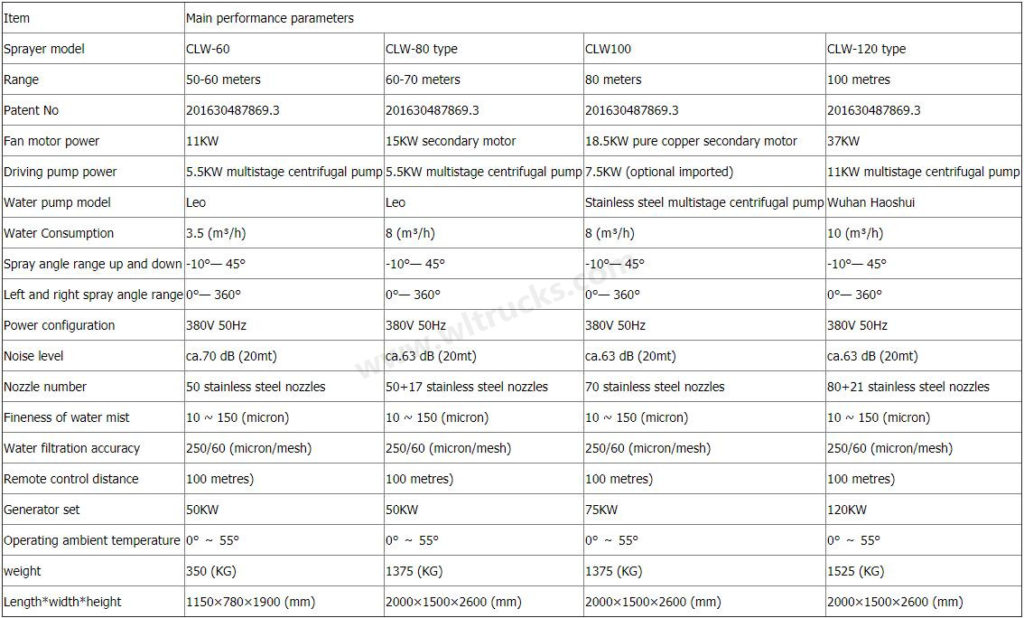

80m to 120 meters fog gun machine Specifications:

New craft:

disinfectant trucks Optional configuration:

Inspection Training:

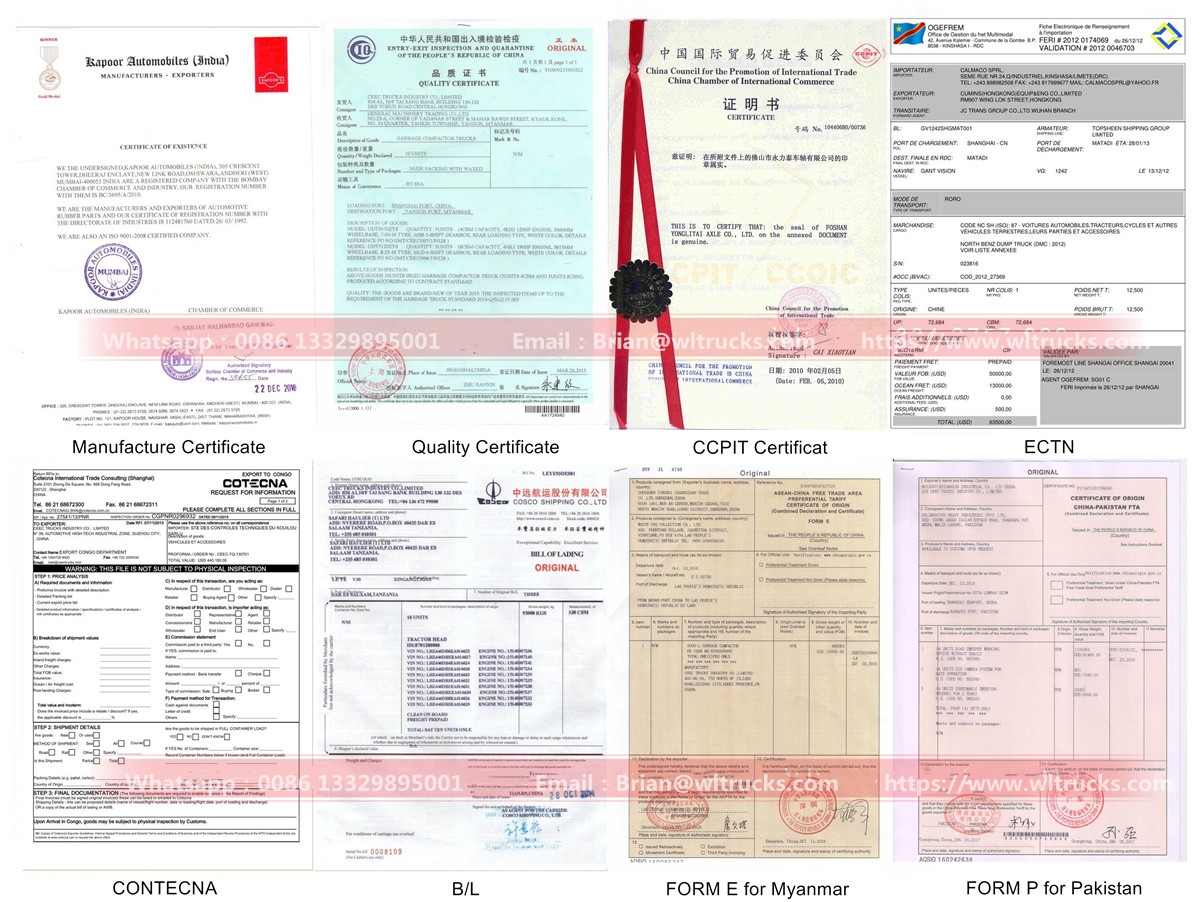

—- SGS, BV, COTECNA, CE certification.

—- Local engineer training support.

Free Parts:

— Free parts for 12 months.

—- Supply of original parts.

—- DHL serves 7 days worldwide.

Disinfection vehicle Factory Advantage:

— 16 years of design and export experience.

—- 100% customized trucks.

—- Quick delivery guarantee.

Export Documents:

—- Serving more than 80 countries and regions.

—- Professional guidance on import documents.

—- CO, FORM E, FORM P, pre-implantation inspection …

Shipping:

—- Maximize your shipping costs.

—- Professional guidance on import documents.

—- Safe, fast and timely

Bulk order case:

—- Fast shipping to all parts of the world.

—- The truck color and logo can be customized.