1. Vehicle description

1. Overview

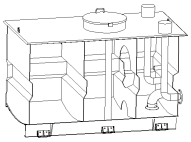

| CLW5100 GXF PM30 / Q-type foam fire, CLW5 100 GXF SG30 / Q-type tank fire, using Qingling QL1100A8MAY chassis converted. The vehicle consists of two parts: the firefighter cabin and the body. The cabin is changed from single row to double row. It can take 2+3 people. The car has a built-in tank structure, the front of the body is an equipment box , and the middle is a water tank. At the rear is the pump room. The carrier liquid for the high quality carbon steel tank, and chassis elastic connection, carrying water 2000kg (PM30) / 3000kg (SG30 ), the amount of foam liquid 1000kg (PM30), dried equipped Shanghai Shen Fire Equipment Co CB10 /. 3 0 Type Low pressure fire pump, rated flow 30L/S, roof mounted PL 24 ( PM 30) or PS 30 W (SG 3 0) vehicle fire monitor produced by Chengdu West Fire Fighting Machinery Co., Ltd. The biggest feature of this car is its large liquid carrying capacity, good handling and easy maintenance. It can be widely used in public security fire brigade, factories and mines, communities, docks and other places to fight large oil fires or general material fires. The fire performance of the whole vehicle complies with the requirements of GB7956-2014 standard; the chassis has passed the national mandatory product certification; the engine emissions meet the requirements of the fifth stage limit value of GB17691-2005 (National V standard); the whole vehicle has passed the inspection of the National Fire Equipment Quality Supervision and Inspection Center , CCCF is applying. |

2. Main parameters of the vehicle

| Outside dimensions | 7690 ×2250×3000mm |

| Maximum total mass | 9700kg |

| Carrier volume | Foam car water 2150kg, foam 950kg, water tank car water 3100kg |

| Maximum speed | 90km/h |

| Fire pump rated flow | 30L/s 1.0MPa |

| Rated flow of fire monitor | Foam truck: 24L/s 1.0MPa Water tank truck: 30L/s 1.0 M Pa |

| Fire gun range | Foam truck: foam ≥40 m water ≥45 m water tank truck: ≥55 m |

| Specific power | 141/9.7=14.536 |

| Approach / departure angle | 19° /1 3° |

Second, the chassis

1. The main parameters of the chassis

| model | QL1100A8MAY | |

| manufacturer | Qingling Motors Co., Ltd. | |

| Engine rated power | 141kw | |

| engine capacity | 5193ml | |

| Engine emission standards | GB17691-2005 National V | |

| Drive form | 4×2 | |

| Wheelbase | 4475mm | |

| Maximum allowable gross weight | 10000kg | |

| Minimum turning radius | ≤19m | |

| Gearbox | Manual |

2. The crew room

| structure | Flat head, four doors, restructured double row | |

| Number of passengers | 2+3 people | |

| Driver position | Left | |

| device | Fire control instrument panel and police light control box are installed at the original car dashboard1. Alarm;2. Power switch control switch and indicator light;3. Additional power switch; |

3. Bodywork structure and performance parameters

| General layout | The vehicle consists of two parts: the firefighter’s cabin and the body. The body layout uses a built-in tank structure. The left and right sides are equipment boxes, the middle is a water tank, and the back of the equipment box is a pump room. |

Equipment box and pump room

| structure | The main frame structure is welded with high-quality square tubes, and the outer decorative plate is welded with carbon steel plates. The roof is non-slip and can be walked on . (Aluminum alloy square tube welding can be used according to user needs) | |

| Equipment box | The equipment boxes are located on both sides of the rear of the passenger compartment, and are equipped with aluminum alloy rolling doors with lighting lamps inside. Storage boxes are set in the equipment box room according to demand. | |

| Pump room | The pump room is located at the rear of the vehicle, with aluminum alloy rolling shutters on both sides and the back, with lights inside . | |

| Insulation position: Install fuel heater (optional according to customer needs) | ||

| Ladder and handle | The rear ladder is made of aluminum alloy two-section flip ladder. It is used when it is not more than 350mm from the ground. The handle of the car is made of non-slip round steel pipe with a groove on the surface and the surface is sprayed with plastic. |  |

| 2. Water tank | ||

| capacity | 2000kg (PM30), 300kg (SG30) |

|

| Material | High-quality carbon steel with a thickness of 3mm (can be made of stainless steel and PP according to user needs) | |

| Tank fixing | Flexible connection with chassis frame | |

| Tank settings | Manhole: One manhole with a diameter of 460mm, with quick locking/opening device | |

| Overflow port: one DN65 overflow port | ||

| Remaining water outlet: set a DN40 water tank to discharge remaining water outlet, equipped with ball valve | ||

| Water injection port: connect two DN80 ports on the left and right sides of the water tank | ||

| Water inlet and outlet: one water tank to the water inlet pipe of the pump, DN100 valve, which can be pneumatically and manually controlled, one water pump to the water tank filling pipe, DN65 valve, which can be pneumatically and manually controlled | ||

- Foam tank

| capacity | 1000kg (PM30) |  |

| Material | High-quality carbon steel with a thickness of 3mm (can be made of stainless steel and PP according to user needs) | |

| Tank fixing | Flexible connection with chassis frame | |

| Tank settings | Manhole: provided DN460 manhole . 1 th, with quick locking / opening, automatic pressure relief device | |

| Overflow port: provided DN40 overflow port . 1 th | ||

| Raffinate discharge port: provided . 1 th DN40 foam tank raffinate discharge port | ||

| A foam outlet: provided . 1 th DN40 foam tank to pump out the foam tube |

4. Water system

1. Water pump

| model | CB10 /30-RS low-pressure vehicle fire pump | |

| form | Low pressure centrifugal | |

| Limited Data | 30L/s @1.0MPa | |

| Rated outlet pressure | 1.0MPa | |

| Maximum suction depth | 7m | |

| Water diversion device | Built-in sliding vane pump | |

| Diversion time | Maximum suction depth≤50s |

2. Piping system

| Pipe material | High-quality seamless steel pipe | |

| Suction pipe | There is a DN100 suction port on the left and right sides of the pump room | |

| Water injection line | Two DN65 water injection ports are provided on the left and right sides of the water tank, and a DN65 water pump is provided in the pump room to inject water into the tank | |

| Outlet pipe | There is a DN80 water outlet on the left and right sides of the pump room , with a shut-off valve and a cover | |

| Cooling water pipeline | Cooling water pipeline and control valve with cooling power take-off |

5. Fire extinguishing device

1. Car water cannon

| model | PS30W | |

| manufacturer | Chengdu West Fire Machinery Co., Ltd. | |

| Rotation angle | 360° horizontal rotation | |

| Maximum elevation/depression angle | Depression angle ≤-15°, elevation angle ≥+60° | |

| flow | 30L/S | |

| Range | ≥55m |

2. Car foam gun

| model | PL24 | |

| manufacturer | Chengdu West Fire Machinery Co., Ltd. | |

| Rotation angle | 360° horizontal rotation | |

| Maximum elevation/depression angle | Depression angle ≤-15°, elevation angle ≥+45° | |

| flow | 24L/S | |

| Range | Foam ≧ 40 m water ≥45 m |

6. Fire control system

The control panel mainly includes two parts: cab control and pump room control

| Cab control | Water pump disengagement, warning light alarm, lighting and signal device control, etc. | |

| Pump room control | Bodywork main power switch, parameter display, status display |

Seven, electrical equipment

| Additional electrical | Set up an independent circuit | |

| Auxiliary lighting | Firemen’s room, water pump room and equipment box are equipped with lights respectively, and lighting and indicator lights are set on the control panel | |

| Strobe light | Install red and blue strobe lights on both sides of the body | |

| Warning device | Long row of red warning lights, installed on the top of the cab | |

| Siren, the control box is under the driver’s front | ||

| Fire field lighting | Install a 35W fire searchlight at the back of the jacket |

8. Surface treatment

| Topcoat | High-quality domestic paint |

| colour | The main color of the outer surface of the car body is RO3 fire red |

9. Arrangement and equipment of on-board fire fighting equipment

1. Equipment layout

| 1 | According to the actual needs of firefighting, according to the firefighting operation procedures, take it nearby. |

| 2 | Use special jigs for anti-corrosion, anti-vibration, anti-shedding and anti-scratch. |

| 3 | Signs are eye-catching, multi-person operation, non-interference. |

2. Equipment and equipment (standard)

| 1 | straw | 100 × 4 meters | 2 | root | Threaded |

| 2 | Water filter | FLF100 | 1 | Piece | Threaded |

| 3 | Trap | FII80/65 × 3-1.6 | 1 | Piece | Internal button |

| 4 | Water trap | JII100/65 × 2-1.0 | 1 | Piece | Internal button |

| 5 | Hose | 13-65-20 | 4 | plate | Low pressure; |

| 6 | Hose | 13-80-20 | 4 | plate | Low pressure; |

| 7 | Reducing interface | KJ65/80 | 2 | Piece | Internal button |

| 8 | Water-retaining cloth | DT-SB | 4 | Piece | |

| 9 | Hose hook | 4 | Piece | ||

| 10 | Ground fire hydrant wrench | QT-DS1 ; length 400 | 1 | Piece | |

| 11 | Underground hydrant wrench | Long 860 | 1 | Piece | |

| 12 | Suction pipe wrench | FS100 | 2 | Piece | |

| 13 | DC switch water gun | QZG3.5/7.5 ; 65 | 1 | support | Low pressure; |

| 14 | DC Flowering Water Gun | QZK3.5/7.5 ; 65 | 1 | support | Low pressure; |

| 15 | Foam gun | PQ4/0.7Z | 1 | support | |

| 16 | Foam pipette | 40*2700 | 1 | Piece | |

| 17 | |||||

| 18 | Fire extinguisher | 3kg | 1 | With | |

| 19 | Fire waist axe | Length 390 ; GF-285 | 1 | Piece | |

| 20 | Rubber hammer | 1 | Piece | ||

| twenty one | Rechargeable portable lighting | 1 | Piece |

3. Optional configuration and equipment

| 1 | Automatic charging and inflating device | 24V | 1 | set | |

| 2 | Air backrest | 3 | set | ||

| 3 | Air breathing apparatus | Number of members | set | ||

| 4 | Hose bridge | rubber | 2 | vice | |

| 5 | Telescopic ladder | 1 | vice | ||

| 6 | Hand pump | 1 | station | ||

| 7 | Breaking tools | 1 | set | ||

| 8 | Other fire equipment |