Product Specifications:

|

Vehicle name:

|

Sinotruk 8000 liters steyr fire truck

|

Vehicle model:

|

CLW5341GSSD3

|

Dimensions:

|

8205×2485×3375

|

||||

|

Chassis model:

|

ZZ5207N4617E1

|

Engine:

|

Sinotruk 290 hp / 206kw

|

Tank volume:

|

6~8 cubic meters

|

||||

|

Drive type:

|

4×2

|

Emission Standards:

|

Eruo 4

|

Number of passengers in the cab:

|

2+4 people

|

||||

|

Number of axes:

|

2

|

Front track:

|

1703mm

|

Tire specifications:

|

1000R20

|

||||

|

Wheelbase:

|

4700mm

|

Rear track:

|

1494mm

|

Number of leaf springs:

|

7/5+6

|

||||

|

Axle load:

|

6600kg

|

Maximum speed:

|

99km/h

|

Anti-lock system:

|

Have

|

||||

|

Front overhang / rear overhang

|

1765/1830mm

|

Number of tires:

|

6

|

Close to the departure angle:

|

25/13°

|

||||

|

Total quality:

|

16800kg

|

Rated quality:

|

6600kg

|

Curb quality:

|

6175kg

|

||||

|

specification:

|

Low pressure of fire pump: Flow:CB10/60-RS, pressure: 1.0MPa Water

intake time ≤ 35 Maximum suction depth is 7m, flow rate: 60L/s, pressure: 1.0MPa Fire cannon Model: PS60W , flow: 60L / S, range: ≥ 70m, pressure: ≤ 1.0MPa, pitch angle -22 ° ~ +81 °, angle of rotation 360 ° |

||||||||

| other: | Brake system: service brake system, dual-circuit air pressure brake: parking brake, spring energy storage brake: auxiliary brake, engine exhaust brake. Minimum turning radius ≤19m | |||||||

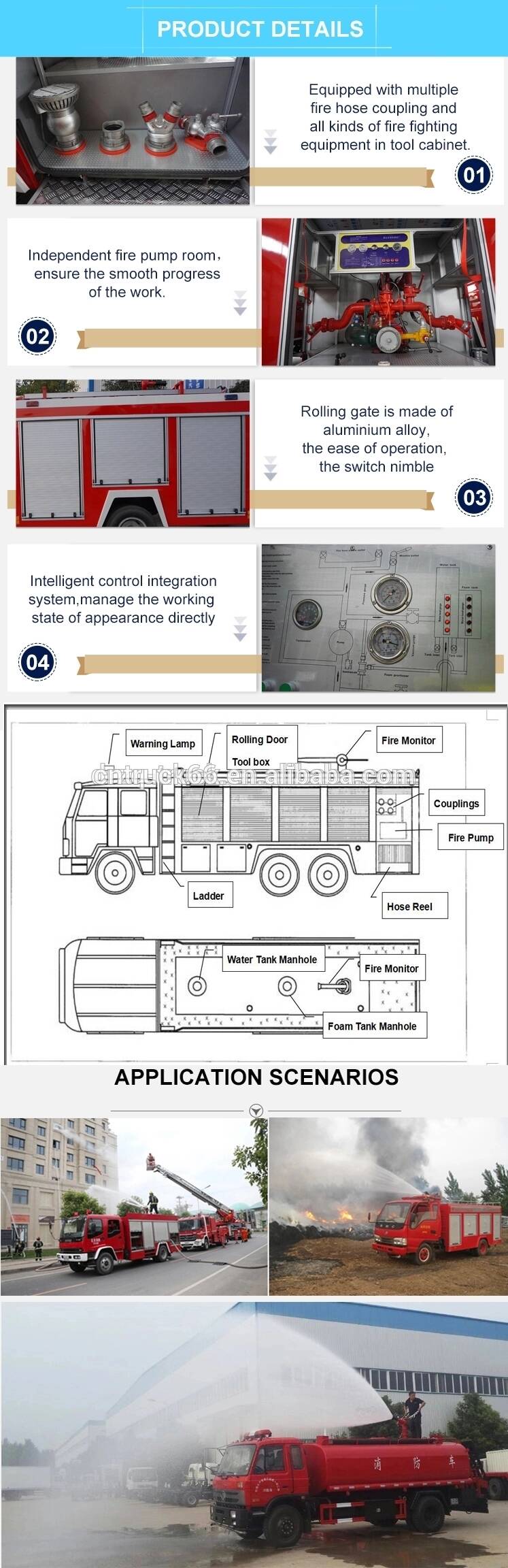

| Overall layout: The vehicle consists of two parts: the firefighter’s cabin and the body. The body is arranged in a three-piece structure. The front part is the equipment box, the middle part is the water tank, and the rear part is the pump room. The tank body is a parallelepiped box-type container. tank. | ||||||||

| PTO | Structure and form | Integral box type, full power, sandwich type, forced adjustable circulating water cooling, splash oil lubrication | ||||||

| Cab | Structure type | The overall four-door double-row flat head, additional crew room, a total of 6 people can be seated, the driver position is left | ||||||

| Equipped with fire-fighting facilities | The instrument panel of the original car is equipped with a fire control instrument panel and a police light control box, which is equipped with 1. an alarm; 2. a power take-off control switch and an indicator lamp; 3. an additional power switch; | |||||||

| Equipment box | Structure and form | The main frame structure is welded with high-quality square tubes, and the outer decorative plate is welded with carbon steel plates. The roof is non-slip and can be walked on. (Aluminum alloy square tube welding can be used according to user needs) | ||||||

| Equipment box | The equipment box is located at the rear of the passenger compartment, with aluminum alloy rolling doors on both sides and lighting lamps inside. Storage boxes are set in the equipment box room according to demand. The side skirt is equipped with a tool box and a roller shutter door, where small tools can be placed. | |||||||

| Container | Material | High-quality carbon steel with a thickness of 5mm (can be made of stainless steel and PP according to user needs) | ||||||

| Jug | Manhole: one DN460 manhole, with quick lock/open device overflow port: one DN65 overflow port, one surplus water outlet: one DN40 water tank for surplus water outlet, and a ball valve water inlet: in the water tank Connect a DN80 interface water inlet and outlet on the left and right sides : set a water tank to the water inlet pipe of the pump, DN150 valve, pneumatic and manual control, set a water pump to the water tank filling pipe, DN65 valve, pneumatic and manual control |

|||||||

| Foam tank | Manhole: one DN460 manhole, with quick lock/open, automatic pressure relief device overflow port: one DN40 overflow port one excess liquid port: one DN40 foam tank to discharge excess liquid port :Set a DN40 foam tank to the water pump out of the foam tube |

|||||||

| Volume | Water tank: 8000kg | |||||||

| Pump room | Structure and form | The pump room is located at the rear of the vehicle, with aluminum alloy rolling doors on both sides and the back, with lights inside, and some common equipment can be placed on both sides of the pump room | ||||||

| Equipped with fire-fighting facilities | Water filters, water collectors, water distributors, water guns, reducers, suction pipe wrenches, etc., can also be equipped according to special needs: such as hand-lifted motor pumps, fuel heaters, etc. | |||||||

| Ladder | Ladder and handle | The rear ladder is made of aluminum alloy two-section flip ladder. It is not more than 350mm away from the ground when in use. The handle on the car is made of non-slip round steel pipe with grooved surface and the surface is sprayed with plastic. | ||||||

| Fire Pump | model | CB20.10/30.60 type medium and low pressure vehicle fire pump | ||||||

| Structure and performance | structure | Atmospheric centrifugal | ||||||

| performance | Low pressure | 60L/s @1.0MPa | Diversion time ≤50, the maximum suction depth is 7m | |||||

| Medium pressure | 30L/s @2.0MPa | |||||||

| Water diversion device | Built-in sliding vane pump | |||||||

| Fire cannon | model | PS60W | Range | Water≥70m | ||||

| flow | 60L/S | |||||||

| Maximum elevation/depression angle | : Depression angle ≤-15°, elevation angle ≥+45° | |||||||

| Rotation angle | Water and foam dual purpose fire monitor, 360° horizontal rotation | |||||||

| Piping system | Pipe material | High-quality seamless steel pipe | ||||||

| Suction pipe | There is a DN150 suction port on the back side of the pump room | |||||||

| Water injection line | There is a DN80 water injection port on the left and right sides of the water tank, and a DN65 water pump is installed in the pump room to inject water into the tank | |||||||

| Outlet pipe | There are 2 DN65 and 1 DN80 water outlets on the left and right sides of the pump room, with shut-off valve and ampoule | |||||||

| Cooling water pipeline | Cooling water pipeline and control valve with cooling power take-off | |||||||

| Electrical system | Additional electrical | Set up an independent circuit | ||||||

| Auxiliary lighting | Firemen’s room, water pump room and equipment box are equipped with lights respectively, and lighting and indicator lights are set on the control panel | |||||||

| Strobe light | Install red and blue strobe lights on both sides of the body | |||||||

| Warning device | Long row of red warning lights, installed on the top of the cab. Siren, the control box is under the driver’s front | |||||||

| Fire field lighting | Install a 35W fire searchlight at the back of the jacket | |||||||

| Control system | Cab control | Water pump disengagement, warning light alarm, lighting and signal device control, etc. | ||||||

| Pump room control | Bodywork main power switch, parameter display, status display | |||||||

| Optional part | With sprinkler function: front flushing, rear sprinkling; rear roof lighting; standard CB10/60 type normal pressure pump, optional CB20.10/30.60 medium and low pressure pump, etc. | |||||||

Fire equipment table:

| Serial number | name | specification | Quantity | unit | Remarks |

| 1 | straw | 125×4 meters | 2 | root | Threaded |

| 2 | Water filter | FLF125 | 1 | Piece | Threaded |

| 3 | Trap | FII80/65×3-1.6 | 1 | Piece | Internal button |

| 4 | Water trap | JII125/65×2-1.0 | 1 | Piece | Internal button |

| 5 | Hose | 13-65-20 | 6 | plate | Low pressure; |

| 6 | Hose | 13-80-20 | 6 | plate | Low pressure; |

| 7 | Reducing interface | KJ65/80 | 2 | Piece | Internal button |

| 8 | Water-retaining cloth | DT-SB | 4 | Piece | Internal button |

| 9 | Hose hook | 4 | Piece | ||

| 10 | Ground fire hydrant wrench | QT-DS1; length 400 | 1 | Piece | |

| 11 | Underground hydrant wrench | Long 860 | 1 | Piece | |

| 12 | Suction pipe wrench | FS100 | 2 | Piece | |

| 13 | DC switch water gun | QZG3.5/7.5; 65 | 1 | support | Low pressure; |

| 14 | DC Flowering Water Gun | QZK3.5/7.5; 65 | 1 | support | Low pressure; |

| 15 | Fire extinguisher | 3KG | 1 | With | |

| 16 | Fire waist axe | Length 390; GF-285 | 1 | Piece | |

| 17 | Rubber hammer | 1 | Piece | ||

| 18 | Rechargeable portable lighting | 1 | Piece |

Optional fire equipment table:

| Serial number | name | specification | Quantity | unit | Remarks |

| 1 | Automatic charging device | 12V | 1 | set | |

| 2 | Air backrest | 3 | set | ||

| 3 | Air breathing apparatus | Number of members | set | ||

| 4 | Hose bridge | rubber | 2 | vice | |

| 5 | Telescopic ladder | 1 | vice | ||

| 6 | Hand lift the pump | 1 | station | ||

| 7 | Breaking tools | 1 | set | ||

| 8 | Other fire equipment |