ISUZU ftr 20 m to 38 m aerial platform truck

ISUZU ftr 20 m to 38 m aerial platform truck Application area:

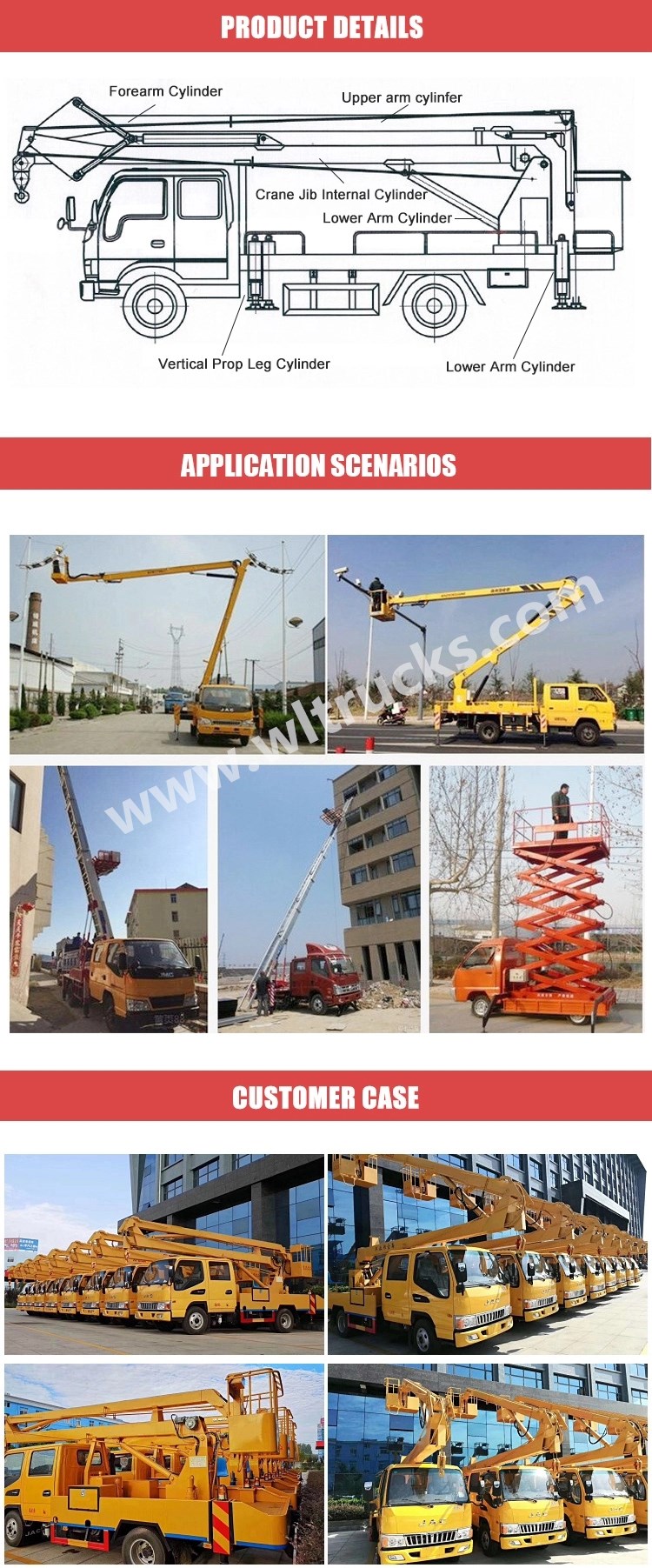

Aerial platform vehicles are widely used for installation, maintenance and ascending operations in industries such as municipal administration, electric power, street lights, advertising, communications, photography, gardens, shipbuilding, transportation, docks, airports and ports, rescue and rescue, large industrial and mining enterprises, etc.

Aerial platform truck are also known as: street light repair trucks, hydraulic lift trucks, ascending platform trucks. Our company specializes in the production of 6 meters, 10 meters, 12 meters, 13.5 meters, 14 meters, 16 meters, 18 meters, 20 meters, 22 meters, 24 meters , 28 meters, 32 meters, 38 meters, 45 meters aerial platform trucks, lift trucks, products are widely used in electric power, street lamps, municipal Aerial work areas such as gardens, communications, airports, shipbuilding, ship repair, transportation, advertising, photography, etc. According to the type, it is mainly divided into: vertical lift type (also known as scissor type) aerial work truck, folding arm type lift aerial work truck, self-propelled aerial work platform, telescopic boom type aerial work truck, and ladder truck.

ISUZU ftr 20 m to 38 m aerial platform truck specification:

|

Aerial work platform truck

|

||

|

#

|

Descriptions

|

Specifications and types

|

|

General

|

Truck Brand

|

Chengliwei (our brand)

|

|

Chassis Brand

|

Japanese Chassis

|

|

|

Approx. Dimension

|

8500*2500*3700 mm

|

|

|

GVW./Kerb Wt.

|

9105 / 8910 (Kg)

|

|

|

Cab

|

Cab Capacity

|

3 persons’ seat

|

|

Air Conditioner

|

Air Conditioner is optional

|

|

|

Chassis

|

Drive Type

|

4×2,lefthand drive/

Righthand drive is optional

|

|

Fuel Type

|

Diesel

|

|

|

Engine Make & Model

|

Chongqing Wushiling

|

|

|

Power

|

190 HP

|

|

|

Displacement

|

5193 ml

|

|

|

Emission Standard

|

Euro II or EURO III or Euro V

|

|

|

Wheelbase/No.of axle

|

4475 mm / 2

|

|

|

Tyre Specfication

|

8.25R20 14PR

|

|

|

Tyre Number

|

6 tyres and 1 spare tyre

|

|

|

Max Speed

|

100 km/h

|

|

|

Paint

|

Automative metallic paint

|

|

|

Tops Parts

|

Max Working Height

|

18m

|

|

Platform Dimension

|

1080*610*1100mm

|

|

|

Max Working Radius

|

7.5m

|

|

|

UAngle of Rotation

|

360 degress

|

|

|

Platform Loading

|

1000kgs

|

|

|

Platform Passenger

|

2 persons

|

|

|

Roating Speed

|

0-2m

|

|

|

Equipment:

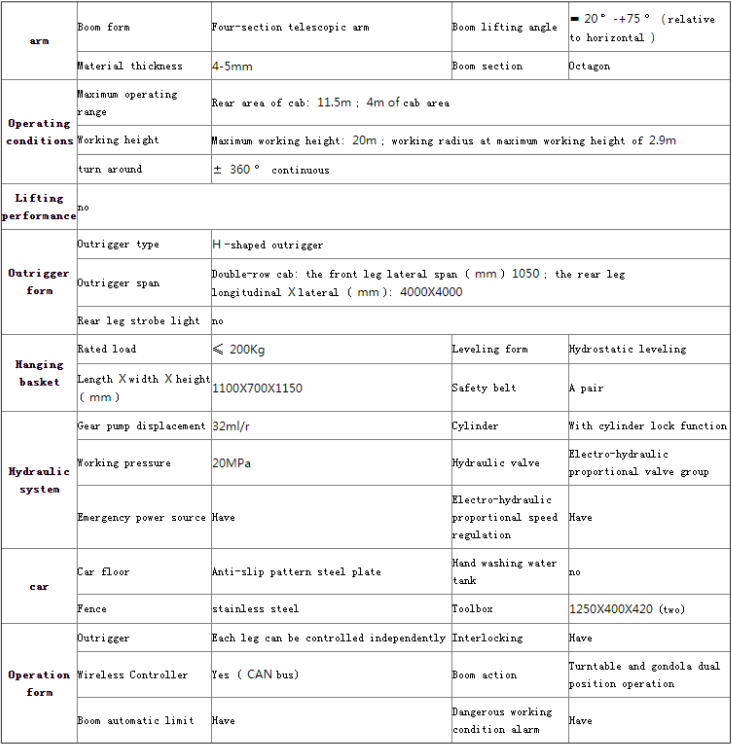

a) Equipped double operation systems;

b) The operationg platform is three-section folding arm;

c) Locking fuction;

d) Four hydraulic H-shap legs which can be adjusted separately.

f) Two tool boxes.

|

||

|

Performance profile

|

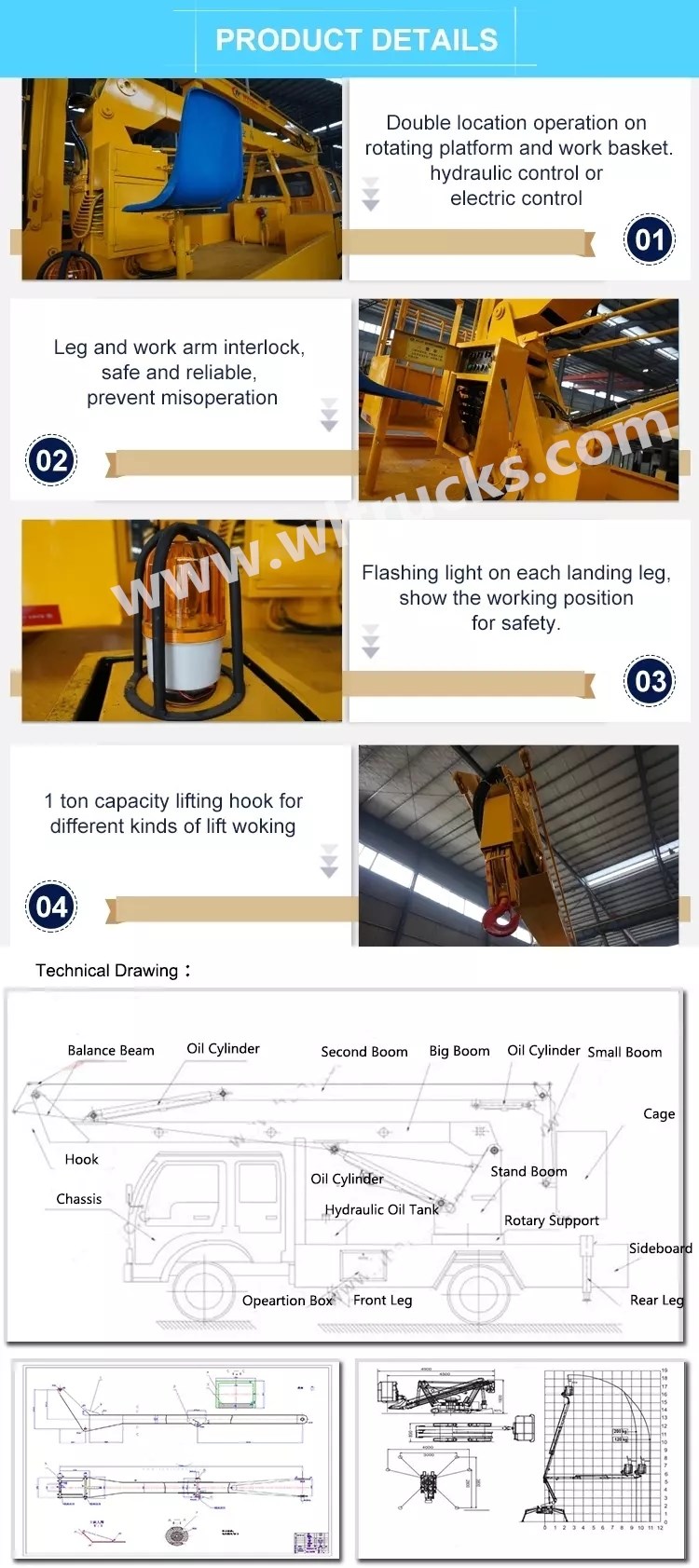

Imported reversing valve and hydraulic cylinder are used for commutation and balance, and the operation is flexible and convenient. Four H-type hydraulic legs are installed in the vehicle, which can be lifted and lowered at the same time to ensure the stability and safety of the whole vehicle during operation. It can be operated up and down, and the hook is installed. The maximum lifting weight of the hook is 200kg. The full telescopic is the working arm and the 360 degree rotation. Up and down two sets of operating systems, complete a variety of work on the work bucket and turntable, optional 14-32 meters series straight arm aerial work. | ||

|

Dedicated configuration

|

Blue brand telescopic boom aerial work car function introduction: 1. The front V rear H-shaped legs have good stability and can be operated simultaneously or separately to adapt to various working conditions. 2, the main supporting hydraulic and electrical components: load-sensitive proportional valves, balancing valves, controllers, etc. are produced by well-known domestic manufacturers. 3. The chassis is equipped with Jiangling Guosan chassis, equipped with air conditioning, and the steering wheel is hydraulically assisted. 4. Configure the vehicle level to ensure the level of the vehicle and ensure safety. 5, computer control, automatic limiting, dangerous work alarm, excellent safety performance. Get off the vehicle and display the real-time operating conditions. 6. Hexagonal working arm, synchronous telescopic, compact structure, high working efficiency and large working range. The telescopic cylinder is external and the chain telescopic mechanism makes it easier to observe the fault point and facilitate maintenance. 7. The whole vehicle electrical appliance adopts CAN bus control system, and the line is neat and simple. There are two operations in the whole vehicle: platform operation, ground operation, safe and reliable, and high work efficiency. 8. The slewing mechanism adopts adjustable type for easy adjustment. 9. Optional 14, 16 , 18, 20, 22,24,26,28,30,32 meters series of aerial work.

|

||

ISUZU ftr 20 m to 38 m aerial platform truck Working parameter: