The maintenance service manual mainly includes the maintenance of road sweeper truck, vacuum cleaner auxiliary engine, fan, suction cup, sweeper system, water circuit, air circuit and circuit system.

The maintenance of the vehicle pays attention to “seven maintenance and three maintenance”, that is, the vehicle should be checked and maintained regularly during the whole life of the vehicle. Early detection and early resolution of problems can achieve the goal of repairing on behalf of repairs, and even not repairing them for life.

One. Road sweeper truck auxiliary engine

1. The water temperature of the auxiliary engine water tank must not exceed 90 degrees Celsius. When the water temperature is too high, it needs to be shut down immediately. Check whether the oil and antifreeze are sufficient, and whether the upper and lower water temperature of the water tank are consistent. (That is, whether the water is circulating in the water tank).

2. Check once or twice a week whether the connection between the engine air intake hose and the stainless steel pipe is sealed, and lock the strong clamp in time. If dust is found on the inner wall of the air intake system, the engine must be turned off immediately and the dust must be cleaned before it can be used.

3. When the engine is started, the time of using the starter each time shall not exceed 5 seconds. Do not exceed 3 times in a row, otherwise the starter may be damaged. You should check whether the fuel is unblocked and whether there is enough fuel in the fuel tank. Dust accumulates in the starter, which may cause a short circuit and burn the starter when it gets wet.

4. The normal working speed of the auxiliary engine is 1800-2000 rpm. It is strictly forbidden to work at excessive speed for a long time, so as not to affect the service life of the engine, and increase or decrease the throttle slowly.

5. Clean up every day to check whether the air filter and oil filter of the engine are blocked. The air filter is blown off the filter element once a day, the oil filter is checked once a week, and the appropriate amount of engine oil is added.

Tow. Road sweeper truck Fan equipment

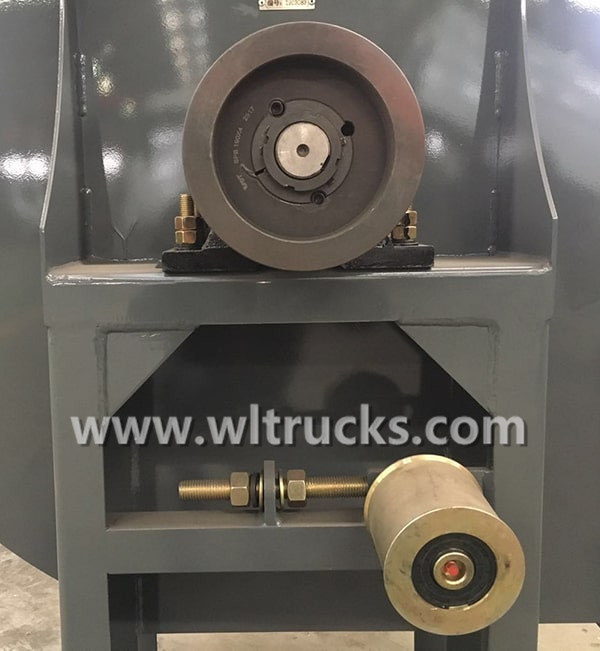

1. The belt tightness of the connection between the fan and the clutch should be appropriate. Add 2kg of vertical load to the middle of each belt, and the sag of 10-20mm is appropriate. Usually the belt will become loose after a period of time. Adjust the belt tightness by adjusting the tension wheel.

2. Regularly check the lubricating oil in the fan bearing housing, and it is advisable not to exceed two-thirds of the bearing housing. Fill high-temperature lithium grease butter.

3. The tension wheel is often filled with butter, and at the same time, check whether the tension wheel fixing screw is loose

4. When sand and gravel enter the fan impeller, it must be cleaned out, because when the fan rotates at a high speed, it will drive the sand and gravel to rotate together. Over time, the impeller and the fan cover will be cut open, causing the fan to be scrapped.

Three, Road sweeper truck hydraulic system

1 The hydraulic oil tank must be filled with high-quality anti-wear hydraulic oil. According to different regions and seasons, fill with different labels of hydraulic oil in northern regions. Fill with low-temperature hydraulic oil in winter. The oil volume should not exceed two-thirds of the tank. If the amount of oil becomes less or discolored, it needs to be filled or replaced in time. The hydraulic oil tank must be sealed well and no dust or foreign objects may enter. If the hydraulic oil contains impurities, it is easy to block the spool in the hydraulic valve, causing the hydraulic valve to jam (if the hydraulic valve is stuck, you need to remove the spool of the hydraulic valve, clean it with diesel oil, and then install it. can.

2 The lamp holder on the hydraulic valve is an electronic component, which will cause a short circuit and burn when water enters. Be careful when washing the car.

3 It is forbidden to move the vehicle when the big tank is in the raised state to avoid damage to the cylinder and the tank.

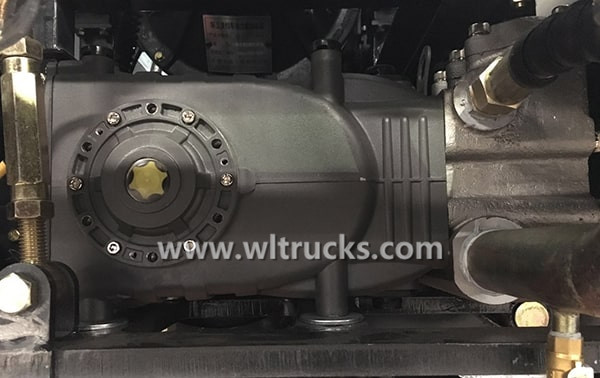

Fourth, the power output system

1 Always check the amount of grease in the power seat. A small amount of gear oil can be injected when filling the grease. The oil level should not exceed two-thirds of the power seat. At the same time, pay attention to whether the fixing screws of the power seat are loose.

2 When the auxiliary engine raises the throttle slowly, if it is too fast, it will easily cause the clutch to wear.

3 No foreign matter such as sand or gravel should fall into the traditional engine disk, otherwise it will increase the wear and tear of the engine gear or even damage it.

Five, Road washing and sweeping truck scanning system

1 Avoid stepping on the hydraulic motor or sweeping plate, which may cause the motor to rotate unevenly.

2 The grease holes on the rotating arms, supporting arms and motor seats are often filled with grease to keep the arms rotating flexibly and reduce wear.

3 After stopping the operation, do not press the sweeping plate to the ground for a long time, which may cause the sweeping brush to deform and affect the cleaning effect.

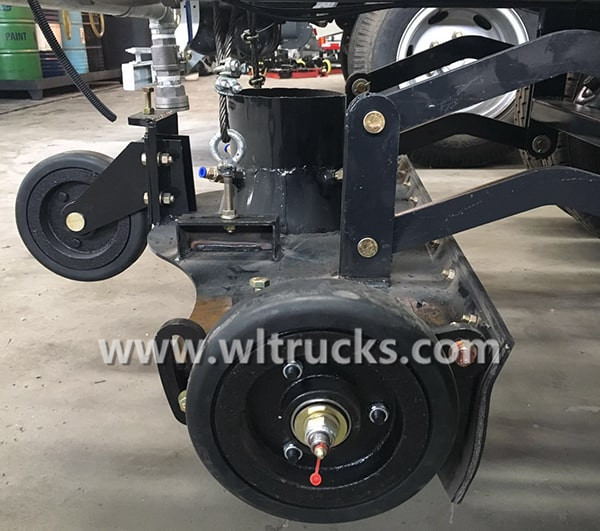

Six, Road sweeper truck suction cup system

1 Frequently check whether the connection of each arm of the suction cup is unobstructed, and whether the wire rope is knotted or interfered to ensure that the suction cup rises and falls normally.

2 Check whether the suction cup connecting hose and gear cover are loose or damaged, and adjust or replace them in time. The height of the suction cup cover can be adjusted after it is worn out, and the distance from the ground is about 10-15 mm.

3 The suction cup vertical shaft, rotating shaft and other parts of the washing and sweeping truck need to be greased regularly to maintain lubrication.

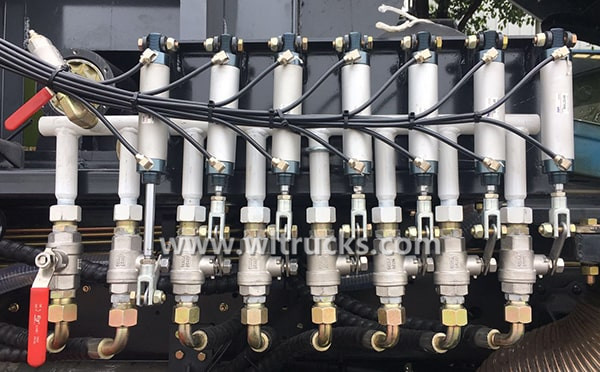

Seven. Waterway

1 The water filter must be removed and cleaned frequently to avoid clogging the nozzle and affecting the cleaning effect.

2 When the sprinkler’s water output is not good and appears intermittent, immediately turn off the water pump to check whether the water filter is blocked by foreign matter, and clean the filter element.

3 Diaphragm pumps, plunger pumps, and low-pressure water pumps must not run dry without water and keep the water outlet unblocked when working.

4 The piston pump needs to check the oil regularly to ensure normal lubrication. The low-pressure water pump cleans the filter tee regularly to keep the waterway unobstructed. After working every day in winter, be sure to drain the water from the pump body.

Eight. Airway

1 The gas storage tank should be drained weekly (through the drain valve under the tank body) to prevent water from entering the gas valve from the gas pipe, causing the solenoid valve to be short-circuited and burned.

2 Check whether the air valve screw is loose and the cylinder rod diameter is scratched weekly to avoid air leakage.

3 The working air pressure of all air valves is 6.5-7mpa, and the main engine should be started before the auxiliary engine starts, and the air pressure is hit to 6.5Mpa

Nine, circuit

1 The electronic control system is composed of a variety of electronic components. It is forbidden to work with water to avoid damage to the components.

2 Do not expose the touch screen for a long time to avoid reducing the touch screen effect

3 The warranty period of the electronic control system is three months